- Welding first appeared in the Bronze Age

The process of joining metals dates back thousands of years to 15th century Europe. Although not what we think of as welding today, it started the revolution. Forge Welding is the oldest form of welding and has been in use since ancient times. A blacksmith would join two pieces of metal by bringing them to a high temperature and hammering them together.

- Underwater welding invented in 1932

Soviet engineer Konstantin Konstantinovich Khrenov devoted his life to the development of welding technology. He invented the electrodes used for underwater welding in 1932. Soon after, his underwater welding techniques found many practical uses. During World War II, these applications were useful in the repair of bridges and ships.

- First robotic welder introduced

General Motors was the first to use an industrial robotic welder in their automobile factory in 1962. Called the UNIMATE, the machine performed spot welds on automobiles going through the assembly line, as the task was too hazardous for humans to perform. Robotic welding didn’t actually take off on a larger scale until the 1980s.

- 1969: First weld attempted in space

Russian cosmonauts were the first to experiment with welding in space. They tested numerous processes including electron beam welding, low-pressure compressed arc welding, and arc welding with consumable electrodes. The test was almost a disaster, as they nearly blew a hole in the hull of their vessel.

- World’s longest known continuous electroslag weld

Like many bridges, the Bay Bridge connecting San Francisco and Oakland carries a lot of vehicles per day (260,000). These structures sustain much wear and tear. Not surprising, many parts of the bridge have welds. Electroslag welding is a single pass welding process used for thick materials. Each base of the bridge required a continuous weld 33ft high and 2-4 inches thick. Each weld took over four hours to complete. State welding inspectors get the painstaking task of looking over 656 feet of weld!

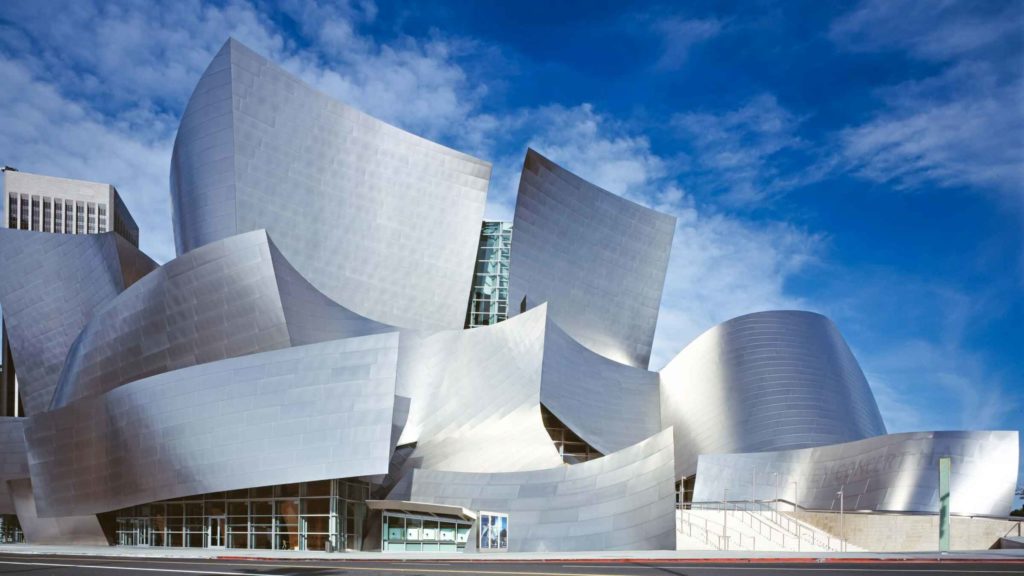

- Famous welded structures

The United States has many famous and historical structures fabricated with the help of welders. The St. Louis Arch is among these iconic structures. Some consider it the tallest man-made monument in the Western Hemisphere. To assemble the arch, 12-foot-long steel triangle sections were welded on site. Workers then fastened these sections together, leading up to the top of the arch.

The Walt Disney Concert Hall in Los Angeles is another stunning sight to see. Made of stainless steel, with beams welded and bolted together. Architect Frank Gehry designed the building based off his love of sailing. If you look at the building just right, it looks like an enormous steel clipper ship. Some commentators call it the “symphony in steel.”