How To Become a Pipeline Welder

A professional known as a pipeline welder is responsible for the enduring assembly and installation of piping systems, examining the materials of these pipes, upholding the welding machinery, and affirming that the pipeline adheres to the required standards. To ensure...

Crucial Skills for a Pipeline Welder

To be a good pipe welder, you need more than just your run of the mill welding skills. You will need additional skills to effectively do your job. The job also requires other important skills such as having good communication skills, physical endurance, being...

Medical Cylinders and Proper Handling

Medical facilities use carbon dioxide, nitrogen, nitrous oxide, and oxygen. These gases are used for lifesaving procedures such as resuscitation, anesthetic, and in powering surgical tools. Proper handling of these gas cylinders is critical. If mishandled these gases...

The Importance of Quality Welding Supplies for Safe Welding

Welding is an essential process that requires expertise and proper welding supplies. It is important to understand that welding can be dangerous if the proper precautions are not taken. That's why the importance of quality of welding supplies plays a crucial role in...

Importance of Proper Maintenance for Your Welding Equipment

Welding is a crucial process in many industries, including construction, manufacturing, and automotive repair. To ensure that welding equipment performs at its best, proper maintenance is essential. Neglecting maintenance can result in equipment failure, reduced...

Dry Ice Uses

Dry ice is a versatile and unique tool that has a wide range of uses. The solid form of carbon dioxide, dry ice is popularly used in the food and medical industries. But its uses go beyond that. Let's take a closer look at some of the common uses of dry ice. 1....

Safety Tips for Handling and Storing Welding Gases

Welding gases are widely used in various industries, but they can be dangerous if not handled and stored properly. Here are some safety tips to help make handling and storing welding gases easy. 1. Understand the properties of the gas you are using Different welding...

The 5 Highest-Paying Welding Jobs

Wondering what the highest-paying welding jobs are? Here are the current top 5 highest-paying welding jobs. Rig WelderAnnual Salary: $52,000 – $207,000 Rig welders are highly paid professionals working long and demanding hours. Their rigorous training...

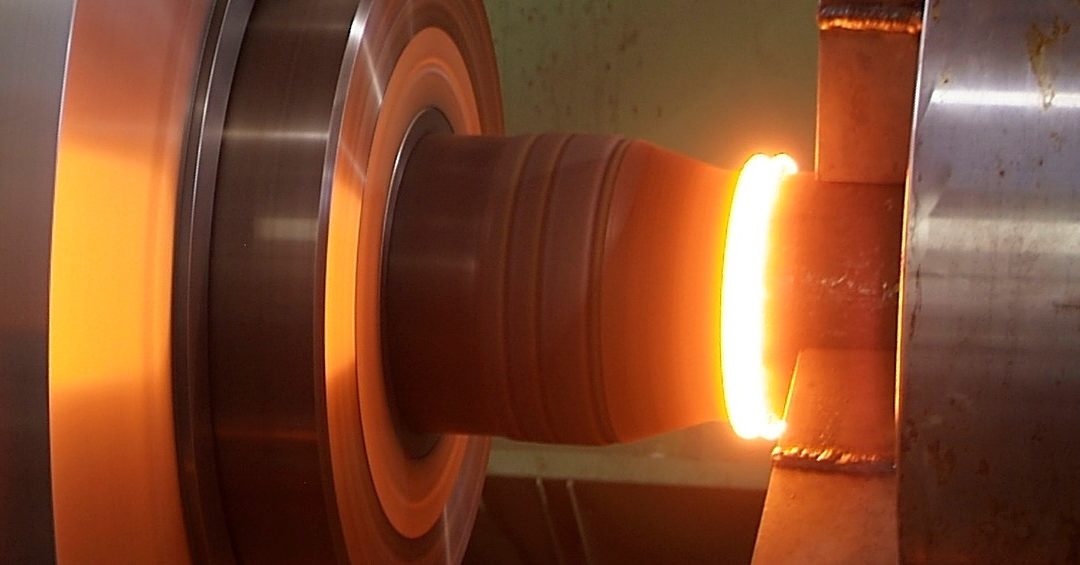

What is Friction Welding?

What the heck is friction welding (FRW) you might ask? Well, it works about like it sounds and can produce some incredibly strong welds. The main component behind this process, as you may have guessed, is friction. This technique originated in England in 1924....

Cobots: Wave of the Future?

Working alongside robots seems like an idea from the future. But cobots (collaborative robots) are now commonly used across a slew of industries including manufacturing, industrial, service, agriculture, and medical. In fact, they’ve been around since 1996, but are...

Compressed Gas Safety

Compressed gas and liquefied gas must follow proper Cylinder and Equipment Safety protocols for a healthy environment. Compressed gas is vital to applications used in a number of industries throughout the world. They are stored in many different types of containers...

National Welding Month

Many are unaware that the month of April has significance for the welding industry dating back to 1996 when it was declared National Welding Month by The American Welding Society (AWS). April was designated to bring awareness to the welding industry, recognize its...

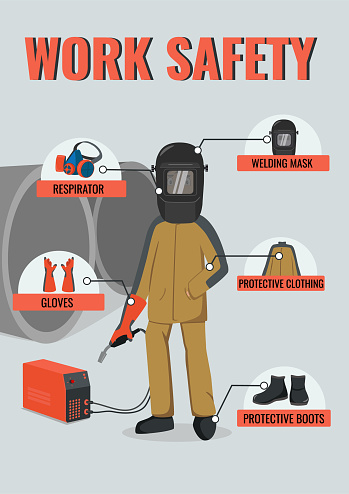

PPE 101: Equipment and Safety Checklist

Whether you are new to the welding field or a seasoned professional, it never hurts to have a refresher when it comes to PPE. Proper Safety & Handling is a must, and we understand some things are easy to overlook. That is why we’ve put together a handy...

Welding Jobs Will Be in High Demand in 2022

As the economy begins to recover in 2022, there will be many openings available in manufacturing, maintenance and repairs, and construction. Aging infrastructure will push the development of new buildings, bridges, and roads—all requiring the expertise of welders,...

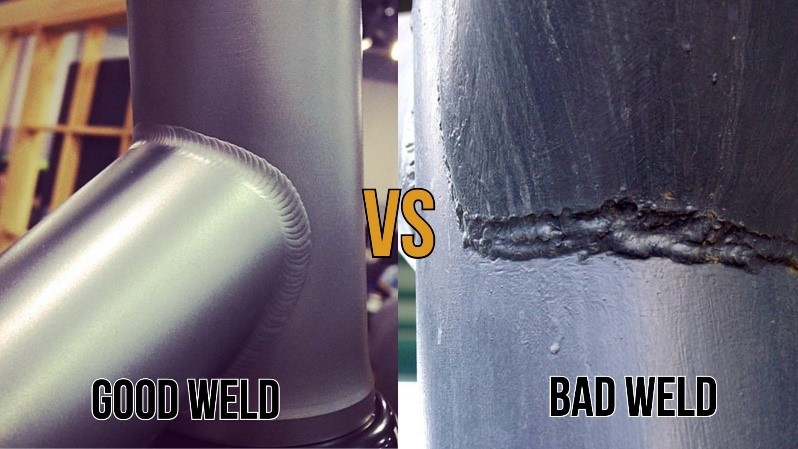

Common Welding Mistakes and How to Avoid Them

Properly maintaining and operating equipment produces a quality product, but also prevents costly mistakes and headaches down the road. Having to repair and rework poor welds will eat away at your bottom line. In this article, we’ll go over some common welding...

Specialty Gases

If you’re in search of a unique gas for a particular purpose, a carefully developed gas mixture can deliver the results you need. Applications that use specialty gases are almost endless. Specialty gases are frequently used in a number of different...

Dry Ice: Uses and Applications

You may be surprised to learn that dry ice has a long list of useful applications for everyday use and across many industries. Industrial, medical, agricultural, food processing, and many others use this diverse product. Whether you simply need to keep food cold on a...

Why Automation?

Have you considered how automation could help you achieve your goals? If you’re experiencing labor shortages, missed schedules and deadlines, inconsistent quality and decreased productivity— automation could be your solution. With an automated solution, you can...

6 Interesting Welding Facts

Welding first appeared in the Bronze Age The process of joining metals dates back thousands of years to 15th century Europe. Although not what we think of as welding today, it started the revolution. Forge Welding is the oldest form of welding and has been in use...

What is Plasma Cutting?

A plasma torch is a powerful tool for cutting through electrically conductive materials such as steel, stainless steel, aluminum, etc. An accelerated jet of hot plasma slices through the work material with ease. Depending on the system, you can cut up to a 6-inch...

Are These Industry Concerns Affecting Your Business?

The past year brought many challenges for the welding and fabrication industry: Rising costs, supply chain issues, long lead times, and hiring/re-hiring as people return to work. Are these issues affecting you and your business? Rising Costs A number of factors...

MIG Welding: Tips for Getting Started

Before you lay your first weld, it’s important to become familiar with the machine’s settings. Proper voltage, wire speed, wire size, and gas are among the first components to get right. Once you find the right balance, you’ll be on your way to producing quality...

Food and Beverage Gas Systems

Food grade CO2 is essential for microbreweries, bars, and restaurants to provide quality beverages, perfectly poured every time. Your favorite sodas and beers require a precise blend of the right gases for a superior product. CO2 and Nitrogen are gases commonly found...

Need an Extra Hand

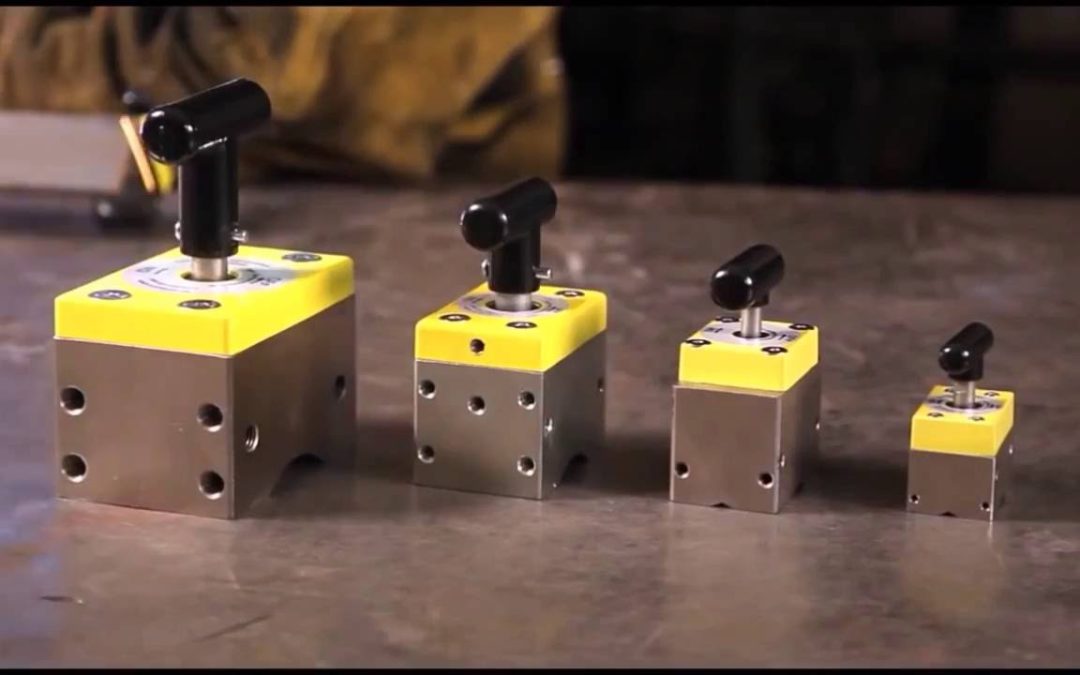

Have you ever thought about Magswitch? What is Magswitch? A magnet with an on / off switch! A full line of magnetic tools that are changing the way you work. Magswitch welding & fabrication magnets are engineered to drive productivity for professional welders and...

Finding the Perfect Welding Hood

Deciding between a passive helmet vs. an auto darkening helmet? Passive welding hoods use a dark tinted lens of shades 9-14 based on level of protection needed, 10 being the most common. They usually are less expensive but require a learned skill to flip down at just...

Why Dry Ice Blasting May Be Right For You?

FACILITY MAINTENANCE: Using dry ice has many benefits when it comes to cleaning facilities and/or equipment. Dirt, soot, grease and oil buildup in production facilities can cause machinery to function improperly creating issues downstream not to mention an unsafe...

THEY ARE NOT ALL CREATED EQUAL: Why You Should Buy Your CNC Plasma Consumables from an Authorized Dealer.

Resist the temptation of “The Deal.” Not all CNC Plasma consumables are created equal. If your last shipment of CNC plasma consumables came from a source such as Amazon or eBay, keep reading, but most importantly, take your finger off the Buy Now button! For many...

Paperless Office

Every business owner and office manager is looking for ways to improve efficiency and cut unnecessary costs. An option often mentioned, but which can be hard to implement, is the ‘paperless office.’ Welders Supply offers paperless billing as a step to help get you...

Safety Issues in the Abrasive World

The following are necessary for personal protection equipment (PPE) in working with abrasives. Most commonly found in the industrial environment are loud noises, sparks and fumes. 1. Goggles with side shields 2. Ear protection 3. Face Mask or respirator...

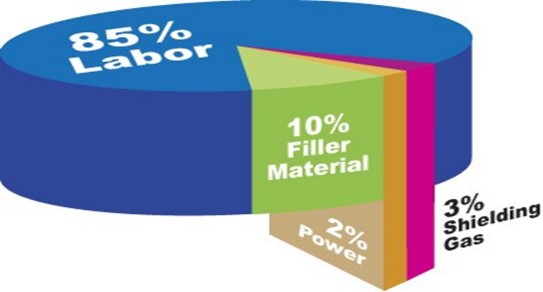

Understanding the Total Cost of Welding

Do you know what it costs to complete a weldment? Have you ever analyzed what factors influence welding costs? Would you like to be more accurate in quoting jobs? It’s time to look at and understand what goes in to the total cost of welding. Welders supply is here to...

Understanding Anti-Spatter

Today’s topic is Anti-Spatter Spray. Most spatter issues can be resolved by having a correct set up of your MIG welder. There are two procedures that anti-spatter is commonly used for. 1. Coating on work piece or on fixture 2. Coating nozzles Most times when you hear...

Flap Discs

Today we look at the differences between Type 27 and Type 29 Flap Discs and Type 1 and Type 27 Cut Off Wheels What is the difference between a Type 27 and a Type 29 Flap Disc? A Type 27 flap disc is referred to as a flat disc. It is best used at a 0-15 degree angle....

What is the cause of rusting on Stainless Steel?

Stainless steel is naturally able to resist rusting because of a passivated chromium oxide layer that forms on the surface. The formation of this layer is called passivation. When anything is done to the stainless such as sanding, wire brushing or welding the...

What Do You Need To Know About Cylinder Tracking?

Do you know how many cylinders you have out? Do you know how long you have had them? Are you concerned with the accuracy of your cylinder rental statement? Are you certain that if a cylinder on your account is returned, no matter by whom, that you will get credit?...

Scotch Brite hand pads and Surface Conditioning Discs

Today we look at Scotch Brite hand pads and Surface Conditioning Discs. This information is based on using a good quality product. Some lesser quality products do not follow the same protocol as good quality providers would. When using surface conditioning discs,...

Abrasives and Finishing

Today we start to look into finishing. The number one rule is to start at the desired finish. If the customer wants 4B finish, which is 120-150 grit, why not start by cutting the weld with a 120 flap wheel. Is it going to be slower, yes, but if you can do it in only...

Understanding the ABCs of a Grinding Wheel

What do the letters A-60-SBF mean? A= Aluminum Oxide C= Silicon Carbide Z= Zirconia Alumina The Middle Number is Grit Size 16- 100 The next letter is Hardness grade: N,O,P Soft Q.R.S Medium T,U,V Hard The last two letters are the Bond: B= Resin BF = Resin with...

Abrasive Grit and Materials. What Does it All Mean?

Abrasive Grit Size Abrasive grit size is determined by dropping the grit through a 1 inch by 1 inch screen with the same number of holes that match the grit, so 24 holes equals 24 grit. If the grit gets stopped in that screen then it is 24 grit. Some of the finer...